|

Oldtymestockings Canadian Sock Machine Museum |

|

|

|

Creelman Brothers' 6 Inch

Circular Knitting Machine

Creelman's 6 inch circular

knitting machines were designed to knit clothing for the

entire family. With Creelman's 6 inch ribber dials and

cylinders, infant jumpers, children's sweaters, ladies'

vests, men's long underwear and a host of other knitted

items could be efficiently and easily knit for the family

and common market. Note the ribber dial and cylinder comparisons of Creelman's

standard 4½ and specialty 6 inch sock machines. Creelman's 6

inch circular knitting machines came standard with 24/72 and

50/100 combinations. |

|

|

|

Creelman Brothers' Banner Knitting Machine

This Canadian sock machine was

the Creelman Brothers' finest. The crescent shaped,

automatic needle latch opener was a standard accessory on

the Banner and World Star Sock machines. Manufactured

in the 1800s, a complete outfit included a 36 slot ribber

dial, a 40 slot ribber dial and 60, 72 and 80 slot cylinders.

Cost was $100.00 back then......imagine that!

|

|

|

|

Creelman Brothers' Conical

Industrial Knitting Machine

The Creelman Brothers' conical

knitting machines were manufactured for industrial use.

Aside from factories and industries, schools for the blind,

children's homes and workhouses acquired industrial knitting

machines for trade. Most industrial sock machines were

operated via the use of large, leather drive belts and industrial

strength motors. A full-length sock could be produced

in a matter of minutes. |

|

|

|

Creelman Brothers' Money Maker A

Knitting Machine

This Canadian sock knitting

machine parallels the Legare 400 sock machine in

design. A typical setup included a 36 slot ribber dial, 54

slot cylinder and 72 slot cylinder. However,

additional combinations were also available.

Parts such as tappet plates,

yarn carriers and cam shells were virtually identical to the

Legare 400 sock machines. One noteworthy difference is the ribber drive pin. Creelman's pin is straight and has

numbers etched in the head. The switch pin, unlike the Legare sock machines,

has a distinctive shape and is composed of steel, not brass. A final variant is

the design of the crank wheel. It features Creelman's

characteristic hub and lacks openings. |

|

|

|

Creelman Brothers' New K Power

Industrial Knitting Machine

The Creelman Brothers produced a

host of machines for private and commercial use. The

New K Power knitting machine was designed for "special

work". It was advertised by the Creelman Brothers as

the best knitting machine for the manufacture of ribbed,

seamless hosiery.

Although an industrial

knitting machine, like Creelman's domestic sock machines,

the New K Power knitting machine utilised

flat ribber dials instead of conical ribber dials. Robust leather belts

and powerful steam motors enabled the production of socks in

a matter of minutes. |

|

|

| |

|

Creelman Brothers' Old World Star Knitting

Machine - under construction |

|

|

|

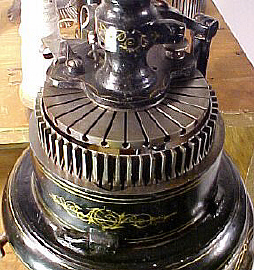

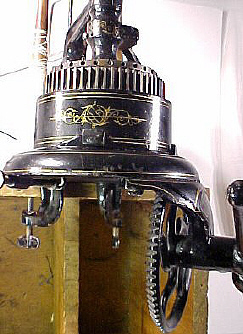

Creelman Brothers' Original World Star

Ribbing Machine

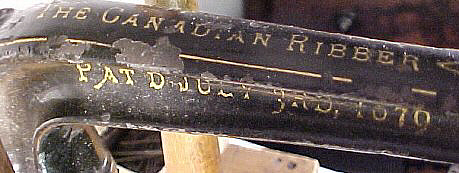

Patented in 1879 as "The Great Hosiery and

Family Ribber", this sock machine was the Creelman Brothers'

first ribbing machine. Creelman's plain machine did not

feature a ribbing attachment and was patented the 22nd of

August, 1874.

|

|

|

|

Harley Kay Industrial Knitting

Machine The

Harley Kay circular knitting machine was an industrial sock

machine manufactured in Georgetown Ontario in the 1940s by the Harley Kay

company. Harley Kay sock machines

were established in Canadian factories to produce hosiery

upon demand. Although individual stands were

available, due to their tremendous weight, Harley Kay

sock machines were generally mounted to wooden platforms or steel

tables. Harley Kay sock machines came standard with

higher slot combinations of 36/72, 42/84 and 60/120. |

|

|

|

Machine à Tricoter Knitting Machine

Manufactured by the Creelman Brothers, this Canadian sock

machine shows a marked resemblance to the Creelman Brothers'

World Star sock machine. Both models featured a

crescent-shaped needle latch opener with yarn feeding

through the centre ribber post. P. T. Legare was

believed to be a firm that sold goods via mail order

catalogue.

|

|

|

|

New

Improved Canadian Automatic Knitting Machine

A late edition, the New

Improved Canadian Automatic sock machine was a novelty item

for special customers. Parts such as tappet plates, yarn

carriers and yarn stands were made of solid brass. Due to

cost expenditures, brass sock machines were rarely produced. |

|

|

| P. T. Legare

3½ Circular Knitting Machine

Created for the construction of

infant and children's socks, P. T. Legare's 3½ diameter sock

machines came standard with 36 slot ribber dials and a 72

slot cylinders. Other combinations such as 28/56, 30/60

and 50/100 were also available. Noteworthy to mention,

infant and children's socks can be easily knit on P. T. Legare's standard 4½ diameter sock machines. Indeed,

all instruction manuals for standard 4½ diameter sock

machines have detailed patterns on the construction of

infant and children's hosiery. |

|

|

|

|

P. T. Legare 47 Circular

Knitting Machine

The P. T. Legare 47 sock machine

was manufactured by the Creelman company. Its design

was much simpler than Creelman's 400 series sock machines.

In particular, the cylinder

tension dials of the P. T. Legare 47 sock machines were

enclosed in the cam shell. Contrariwise, the cylinder

tension dials of Creelman's 400 series sock machines were

constructed separately and readily detachable.

Furthermore, the control plate centre cams were omitted from

the P. T. Legare 47 tappet plates, whilst the 400 series

sock machines had steel control plate centre cams.

The less number of machine

parts and simplicity of design allowed the Creelman firm to

produce the P. T. Legare 47 sock machines at a cost

less than their 400 series counterparts. Noteworthy to

mention, the advertising of the 47 series sock machines was

virtually absent from Creelman's brochures, catalogues and

leaflets. P. T. Legare 47 sock

machines came standard with a 36/54/72 ribber dial and

cylinder combination. |

|

|

|

P. T . Legare 400 Circular

Knitting Machine

P. T. Legare 400 sock machines were

manufactured by the Creelman Brothers. The overall

design is analogous to Creelman's 400 series sock machines.

Despite the numerous similarities, the Creelman Brothers

routinely advertised in brochures, catalogues, leaflets and instruction

manuals that the Creelman Brothers' sock machines were the

best in the trade.

P. T. Legare 400 sock

machines came standard with a 36 slot ribber dial, 54 slot

cylinder and 72 slot cylinder. Notwithstanding, Creelman's 400 series sock machines were available in

13

different ribber dial and cylinder combinations. These

included 24/48, 28/56, 30/60, 32/64, 34/68, 36/72, 38/76,

40/80, 42/84, 44/88, 46/92, 48/96 and 50/100. Both of

the P. T. Legare and Creelman sock machines were constructed

of cast iron, steel and brass. |

|

|

| P. T . Legare World

Star Knitting Machine

Grand and impressive, this

Canadian sock machine resembles the Creelman Brothers'

"Star", "New Star" and "World Star" sock machines in

appearance. Much like the Creelman Brothers' sock machines,

ribber dials ranged between 28 and 50+ slots,

whilst cylinders held

48 to 100+ slots. Aside from label variations, Creelman's

initial design of these large sock machines remained

unchanged. |

|

|

|

Verdun

Semi-Automatic Knitting Machine

The Verdun

Semi-Automatic knitting machine was designed for industrial

use. Features include a lever that raises cylinder

needles out of working position at commencement of the heel

or toe. Similarly, whilst knitting heels and toes, a

switch pin automatically raises cylinder needles out of work.

These aspects allowed the industrial worker to manage

several knitting machines at once. Verdun

Semi-Automatic knitting machines came standard with 36/72

and 42/84 combinations. |

|

|