|

Oldtymestockings American

Sock Machine Museum

|

|

|

|

Ainslie Auto Knitter Knitting Machine

The Ainslie Auto Knitter Sock

Machine was manufactured in Brooklyn, New York by the

Ainslie Knitting Machine Company. Located on Ainslie

Street, the firm's name was synonymous with its location.

Ainslie Auto Knitters were produced during the era of the Canadian Auto Knitters. Hence, differences are

subtle.

Ainslie Auto Knitters were known

for their cherry red handles and deeply notched bed plates.

Unlike standard Auto Knitters whose bed plates were mirror

images, the Ainslie bed plates were asymmetrical and deeply

notched on the right edge. These characteristics distinguish the Ainslie Auto Knitters from the Canadian, Fricke

and Bogan Auto Knitters.

The Ainslie patent label was

fastened to the side of the cam shell with two screws,

usually on top of the original Auto Knitter decal. The

patent label featured gold lettering and trim on a black or

burgundy background. The company's name, address and

serial number of the machine were clearly displayed.

Ainslie Auto Knitters were available in a wide variety of

ribber dial and cylinder combinations. 30/60, 36/72 and

40/80 outfits were quite common. |

|

|

|

American Family

Knitting Machine

Distributed between 1868

and 1873 as the American Family Knitting Machine, this sock

machine was based on Dana Bickford's original patents. The

manufacturing firm, Johnson Clark & Co. of Boston,

Massachusetts & St. Louis, Missouri, ceased trading in

1873. Subsequently, their sock machine patterns and rights

were sold to J. E. Ford & Co.,of Montreal, Canada.

This unique circular sock

machine is quite charming and rare in design. The golden

etchings and green foliage impart a warm appeal.

Unlike traditional sock machines, i.e. Gearharts, Auto

Knitters, Legares, American Family Knitting Machines did not

utilise cams to lift or lower the needles. In fact, the

needle path is engraved inside the cam shell. In addition,

the gear ring is constructed within the 72 slot cylinder.

This sock machine has an

unusual design. Ribbing attachments, yarn rods, yarn

masts and yarn carriers were omitted. Yarn was knitted

directly from bobbins which were seated in the back of the

machine. Heel tension was obtained by threading yarn

into one or both eyelet holes of the wire yarn guide.

Tension for the cylinder was acquired by manipulating the

black screw at the front of the sock machine. This would

lower or raise the needles as they flowed through the needle

path. |

|

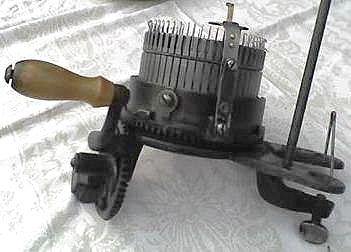

| Auto Knitter Knitting

Machine The

American Auto Knitter sock machine was manufactured at the

height of the depression between the years 1920 and 1940.

This was a time when approximately 600 banks failed each

year; "technological unemployment" entered the nation's

vocabulary; agricultural, energy and coal mining sectors

were continually depressed; construction of textiles, shoes,

shipbuilding and railroads fell $2 billion; more than half

of all Americans were living below a minimum

subsistence level; and investors termed the 29th of October,

1929 as "Black Tuesday". Losses for the month of

October totaled $16 billion, an exorbitant

sum in those days.

With the high cost of steel

and limited industry, the Auto Knitter company constructed

parts of their circular knitting machines from zinc alloys,

commonly known as pot metal. This manoeuvre increased

the survival of the company during one of the most difficult

economic periods of the century. Even so, the Auto

Knitter company, like many commercial enterprises, endured

continued financial strain and eventually went to the

receivers.

The Auto Knitter circular

knitting machine was available in a wide variety of ribber

dial and cylinder combinations. 30/60,

36/72, 40/80, and 50/100 outfits were readily available. Additional combinations could be

acquired on special order. |

|

|

Bickford Family Knitting Machine

First patented

the 10th of September, 1867, Bickford Family Knitting

machines were produced by the Bickford Knitting Machine

Manufacturing Company of Brattleboro, Vermont.

Bickford Family Knitting machines were prodigiously

decorated with gold scrolling on their bed plates, cam

shells and crank handles.

Bickford Family

Knitting machines were intended to meet all of the

domestic needs of the household. The company routinely

advertised that

Bickford Family knitting machines could readily produce

ottoman covers, looped trimmings, carriage and door mats,

hoods, breakfast shawls, blankets, nubias, table and piano

covers, slippers, sashes, capes, tuftings, lamp mats and a

host of other articles.

Bickford

knitting machines were manufactured without ribbing attachments and came

standard with 72 and 100 slot cylinders.

|

|

|

Bogan Harmony Auto Knitter

Known for its emerald green

hue and red stripes, the Bogan Harmony Auto Knitter was

manufactured by the Bogan family from 1984 until the

early 1990s. Like the Fricke Harmony Auto

Knitters, various models underwent modifications and

improvements.

A 30/60 combination, Harmony

Auto Knitter manual and a full array of

knitting accessories accompanied each machine. An

instructional video featuring Norma Bogan was also

available. Norma's classic, elementary style of

teaching continues to assist sock knitters worldwide.

|

|

| Branson Industrial

Knitting Machine

The Branson Industrial sock

machine was first patented on the 6th of May, 1979. A

final patent was attained on the 1st of May 1994.

During this time, the Branson Industrial sock machine

underwent various updates. However, the basic design

of the traditional sock machine and its customary crank

wheel were preserved. With high slot counts and

smaller gauge needles, the Branson Industrial knitting

machine was well-suited for fine, delicate hosiery and

trouser socks. |

|

| Cooperative Circular

Knitting Machine

The Cooperative sock machine was

manufactured in Indianapolis, Indiana. Quite elementary

in design, the Cooperative sock machine was not constructed

with a ribbing attachment. The Cooperative sock machine came standard

with a 72 slot cylinder and customary knitting accessories.

|

|

|

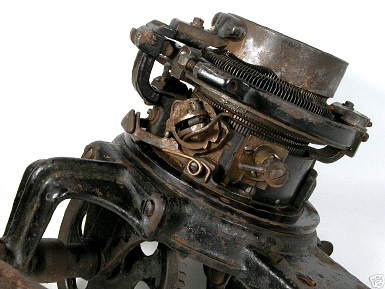

Franz and Pope Automatic Knitting Machine

The Franz and

Pope sock knitting machine was introduced in 1869 as a

family knitting machine for domestic use. Although

its premier purpose was to produce substantial hosiery, it

was also utilised to make fancy apparel, household

adornments and various items of practical use. The Franz

and Pope circular knitting machine came complete with a 72

slot cylinder, a 100 slot cylinder and a standard

array of knitting accessories.

|

|

|

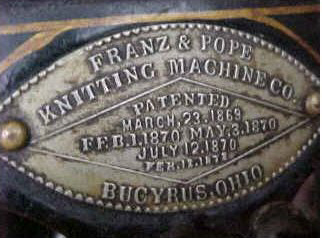

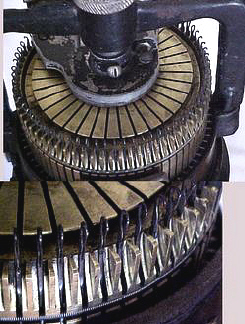

Franz and Pope Nº2 Automatic Knitting Machine

The Franz and

Pope Nº2 sock knitting machine was one of the earliest

circular knitting machines manufactured by the Franz and

Pope knitting machine company. Unlike later models,

the Franz and Pope Nº2 knitting machine lacked lavish decor

and the

conspicuous silver patent label on the crank wheel. The Franz and Pope Nº2 sock

knitting machine was designed to knit work hosiery

from medium and heavy weight yarns. Work hosiery was stronger and

coarser than standard socks and worn chiefly by farmers

and sportsmen. The Franz and Pope Nº2.

circular knitting machine came complete with a 60 slot

cylinder and a standard array of knitting accessories.

|

|

| Franz

and Pope Nº4 Automatic Knitting Machine

The Franz and

Pope Nº4 circular knitting machine was notable for its

lavish embellishments and ornate decor. Golden decals

of birds and foliage encircle the cam shell, base plate and

crank wheel. The Franz and Pope Nº4 circular knitting

machine came complete with a 72 slot cylinder, a 100 slot

cylinder and a standard array of knitting accessories.

|

|

|

Fricke Harmony Auto Knitter 1982

Fricke Harmony Auto Knitters

were manufactured by

Harmony Knitters, Inc.

of Harmony, Maine. Through the joint efforts of

George Fricke,

Ralph McCarthy

and Kerry Bogan,

Harmony

Knitters, Inc. produced American Auto Knitters from the

early 1980s until mid 1984. Thereafter, the company

was sold

to the Bogans.

The bed plates of the Fricke

Harmony Auto Knitters were distinct from their Canadian

forerunners. In particular, the Auto Knitter logo was

not cast into the bed plates. In

addition, a holder for the ribbing attachment was absent.

Despite these differences, the traditional design of the

Canadian Auto Knitter was well-preserved.

The ribber dial of the 1982

Fricke Harmony Auto Knitter featured a wide "cut out" area

at the end of the needle slots. Later models

demonstrated a variation of this design. |

|

|

Fricke Harmony Auto Knitter 1984

Fricke Harmony Auto Knitters

were manufactured by

Harmony Knitters, Inc.

of Harmony, Maine. Stock parts for the machines were

purchased in the 1970s from a French Canadian brother and

sister partnership. Advancing age and infirmity

persuaded the sister partner to leave the business and sell

her share of Canadian Auto Knitter parts to George Fricke.

Castings and cylinders for the

Fricke Harmony Auto Knitters were redesigned. New

parts were constructed from

cast aluminum and machined by

Kerry Bogan. The ribber dials of the 1984 Fricke

Harmony Auto Knitters were modified. Note the slender

slots and tapered contour.

Fricke Harmony Auto Knitters

came standard with a 30/60 ribber dial and cylinder

combination. However, additional outfits such as 36/72

and 40/80 were readily available. |

|

|

Gearhart

Family Knitting Machine

With origins in

Clearfield, Pennsylvania, this America sock machine remains

a true favourite. During its age of manufacture, Gearhart

outfits varied considerably. Ribber dials ranged

from 16 to 70+ slots and cylinders ranged from 48 to 140+ slots.

Needle sizes varied as well. Many of Gearhart's sock

machines were manufactured without ribber attachments to

facilitate use. Wrought iron stands with needle and bobbin

holders were an added attraction. |

|

|

|

|

|

|

|

Gearhart's

1908

Family Knitter

The 1908

Gearhart Family Knitter is one of Gearhart's earliest

knitting machines. Improvements included a wider range

of cylinder outfits, the creation of a curved handle and a

newly designed yarn carrier. Cylinder counts of 52, 54

and 56 enabled the production of infant hosiery and sport

socks. In contrast to the long, straight crank handle

of previous models, Gearhart's 1908 Family Knitter

demonstrated a compact handle.

Cast iron,

flat-faced yarn carriers were the latest improvement.

Previous yarn carriers were manufactured from steel and

consisted of two or more parts. These parts were then

fastened or welded together to create the yarn carrier. Note the

differences between the photographed and catalog depicted

yarn carrier.

The ribbing

attachment remained elementary, for it lacked a lever to

disengage the ribbing attachment and a method to adjust ribber

tension.

Notwithstanding, its simple design and operation

makes the

1908 Gearhart Family Knitter a priceless treasure to many. |

|

|

Home Profit 3¾ Circular Knitting

Machine The

Home Profit 3¾ sock machine was a special edition knitting

machine. Marketed to knit infant and children's socks,

the Home Profit 3¾ sock machine came standard with a 36/72

combination. Note the comparison of the cam shell and

cylinder to Home Profit's standard 4½ sock machine. |

|

| Home Profit 400

Circular Knitting Machine

The Home Profit 400 sock

machines closely resemble the Creelman Brothers' 400 series

sock machines. The shape of the base, cam shell,

cylinder, ribber dial, crank wheel and tappet plate were

virtually identical to Creelman's patents. As one of

the largest manufacturing companies of their time, the

Creelman Brothers' produced numerous machines for private

companies. The P.T. Legare and the Home Profit

Knitting Machine companies were two of note. |

|

|

Home

Profit Knitter The Master Machine

Manufactured by

the Home Profit Hosiery Company until the late 1920s, this

American sock machine hails from Rochester, New

York. Beauty and brass were combined in this spectacular

sock machine. Features included a built in stand; unique,

two prong ribber attachment; solid brass ribber dials

and solid brass cylinders.

A 36 slot

ribber dial and 72 slot cylinder came standard with the Home

Profit knitting machine. However, 48 slot ribber dials

and 96 slot cylinders were also available. Special

edition Home Profit Master machines with 3¾" cylinder

diameters were produced to knit baby socks and children's

hosiery.

Home Profit

knitting machines were advertised by the Home Profit

corporation as "The Master Machine of All Knitters".

This American sock machine remains a gem amongst

collectors.

|

|

|

|

People 's High Speed Knitting Machine

The People's High Speed knitting

machine was manufactured in the early 1890s by Joseph. E. Gearhart in Clearfield, Pennsylvania. The People's High Speed

sock knitting machines were noteworthy for their revolving

needle cylinders. Despite numerous improvements, the

People's High Speed circular knitting machines retained a

remarkable similarity to the modern Gearhart family knitting

machines. |

|

|

Steber Family Knitting Machine

In 1906, Bernard

T. Steber created the Steber Machine Company which remained

in existence in Utica, New

York until 1936. Steber knitting

machines were advertised to homemakers as the ideal sock

machine to produce socks for the war effort. Steber sock

machines came standard with 24 slot ribber dials and 72 slot

cylinders. Additional cylinders of 52, 56, 64, 88, 100,

112, 120 and 140 slots were available at additional cost.

The Steber Machine Company invested a substantial amount of

time in advertising the quality of their machines and

declared that their cylinders were, "...made of a fine grade

of iron, the same as automobile cylinders, and should last a

lifetime." |

|

|

|

Tuttle Nº1 4½ Circular Knitting Machine

Elegance and

ingenuity are the hallmarks of this exceptional knitting

machine. Its soft contours, golden embellishments and

floral decor would persuade any woman to consider its use.

Patented in 1879

by the Lamb Knitting Machine Company as the first circular

knitting machine with a ribbing attachment, the lady of the

house was empowered with the most sophisticated technology

of its time.

Much like a

swan, the ribber attachment stands tall and stately.

Its conical ribber dial was the first of its kind and

permitted use of the ribber when knitting forwards and

backwards. Height of the conical ribber dial was obtained

by adjusting a large thumb screw.

Ribber and

cylinder needles were identical, making needle transfers

swift and easy. Cylinder tension was determined

by regulating a tension wheel which elevated or lowered the

height of the cylinder. Ribber tension was modified in a

similar fashion.

Tuttle knitting

machines have a cunning design. The machine can be set to

knit with the cam cylinder in rotation or the needle

cylinder in rotation when knitting backwards or forwards.

In addition, Tuttle knitting machines can be placed in

neutral, where the crank handle revolves without any motion

of the cam cylinder or needle cylinder.

Tuttle knitting

machines came standard with solid brass counters. The

counters were attached firmly to the base of the machine

with a single screw. Additional models included a 3

inch, 3½ inch

and the rare 4 inch Special Edition Tuttle knitting machine.

Few 4 inch Special Edition Tuttle machines remain in existence. |

|

|

Twombly Circular Knitting Machine

Twombly knitting machines were

manufactured by two firms. The

Novelty Knitting

Machine Company of Hartford, Connecticut manufactured

Twombly knitting machines between 1878 and 1880. The

Twombly Knitting Machine

Company of Boston, Massachusetts produced a later

version between 1880 and 1889.

Both models were composed of

a single ribber dial. A full-length sock could be

easily made on the Twombly sock machine, despite the lack of

a cylinder. Twombly sock machine were customarily

mounted to window sills, ledges or similar sturdy surfaces

and cranked in the same fashion as traditional sock

machines. Golden decals along the base of the machine

were an added attraction. |

|

|

|